Expertise For All Mechanical Needs

For all of your shafts, planetary drives, gearboxes, pinions, and racks, All Geared Up has the expertise to repair and replace them better than new.

- Hoist drives

- Dredge drives

- Slurry pump drives

- Barring drives

- Stacker/reclaimer drives

- Air preheater drives

- Cooling tower fan drives

- Concrete volute pump drives

- Underground/overground conveyor gearboxes

- Mill drive gearboxes

- Shaft mount gearboxes

- Right angle gearboxes

- Parallel gearboxes

- Worm reduction gearboxes

- Planetary gearboxes

Our Services

If a piece of machinery is essential to your business, we can work to repair it. Learn more about our specialized services below.

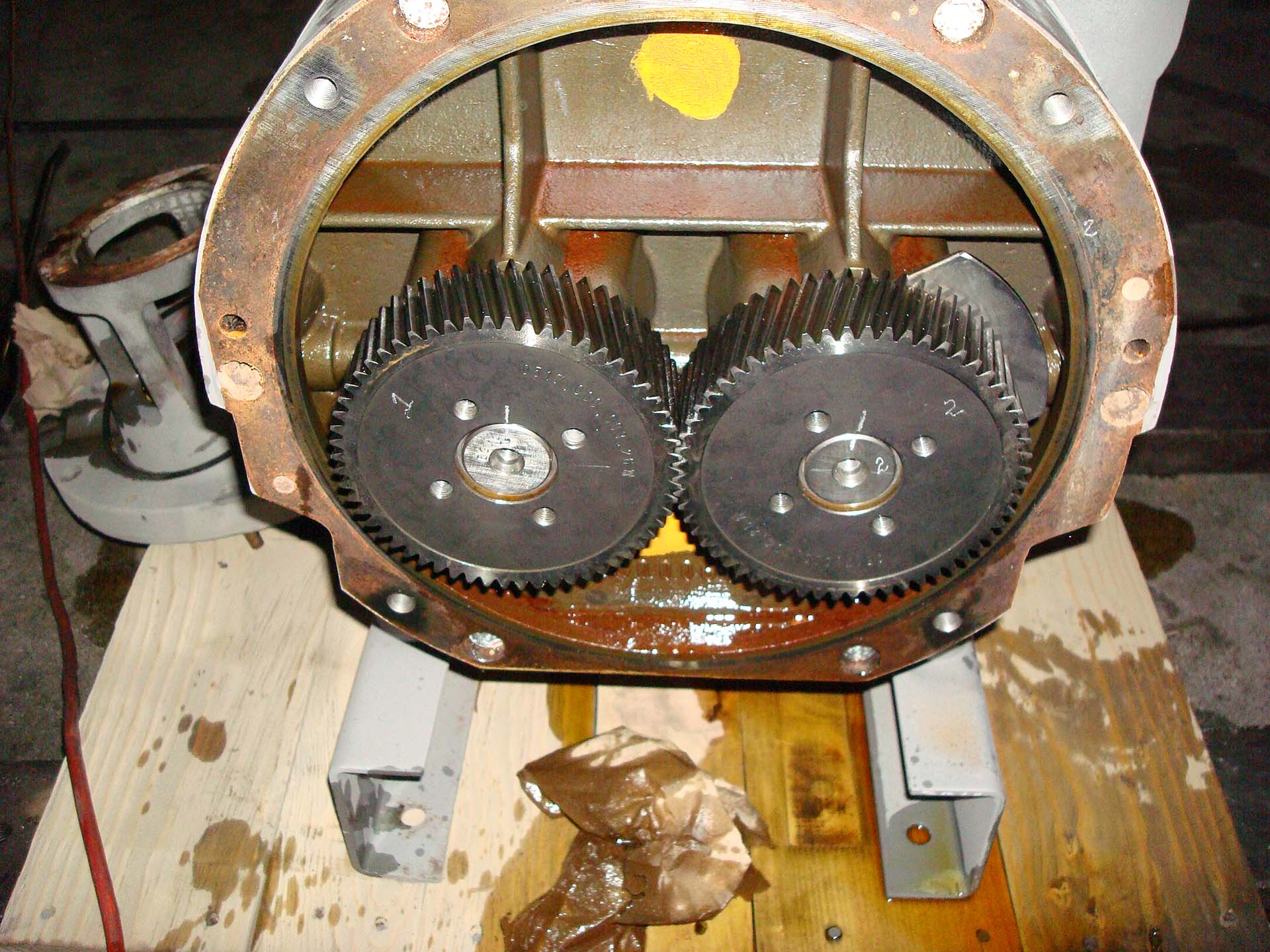

Gearbox Repair

Many pieces of equipment used by manufacturing or processing facilities are highly specialized. In some cases, they are custom-tailored to the facility they serve. This unique construction is why the services of a quality repair and machine shop like All Geared Up are essential.

Gearboxes can be especially complicated because of the precision required of the internal parts and the constant strain they endure.

There are many different types of gearboxes and gears. Fortunately, our skilled professionals are able to service any kind you may have.

- Planetary gearboxes

- Speed increasers and reducers

- Concentric gearboxes

- Parallel gearboxes

- Right angle gearboxes

- Foot-mounted or shaft-mounted gear systems

Popular brands we service include (but are not limited to):

- Toshiba

- Westech

- Eagle Iron Works

- Planetary

- Lohmann

- Kissling

- Dodge

- Hansen

- Camco Ferguson

- California Pellet Mill

- And more

Your gearbox may need new gears to be ground. If so, take a look at our Gear Manufacturing page. Perhaps you require repair for existing parts. No matter how complicated your needs might be, our team can help.

To perform thorough, comprehensive gearbox repair, our first job is to diagnose the root cause. This diagnosis can require a teardown of the gearbox, depending on how many of its internal components can be accessed.

Sometimes, all that’s needed might be fresh oil, but in many cases, a repair is far more complicated.

Once we’ve determined which parts need to be repaired or replaced, we’ll go over the work that needs to be done with you. We don’t do any repairs unless you authorize them!

During our assessment, we’ll test the gearboxes to ensure all parts are working perfectly and there aren’t any inconsistent vibrations in the equipment. Once we’ve gotten the gearbox into fresh-from-the-factory condition, we will reinstall it and get your machinery back to full operation.

Trust All Geared Up to:

Retrofit existing equipment:

- We provide gearboxes that can bolt in place of the old ones

- Provide parts that are completely interchangeable with originals

Upgrade equipment:

Change gear ratios

- Get stronger parts than the originals

Overhaul gearboxes:

- Instead of replacing a gearbox, we can make it good as new

- Repairs may not even require gearbox removal

Inspect equipment:

- Schedule regular maintenance with us to catch problems before they become problematic

- Look for worn parts and replace them before they break

We warranty our work and go to the ends of the earth to ensure you’re happy for years to come.

Pump Repair

Pumps add an extra layer of complication to pieces of equipment because they may be required to move liquids that are particularly harsh on seals and parts. When there’s a leak somewhere in the system, pumps can begin to accumulate dirt and other contaminants that quickly wear down parts.

Depending on the industry you serve, you may have an added requirement to ensure that your pumps are food-safe.

We can repair and replace any kind of pump you have in order to keep your downtime to an absolute minimum.

- Air pumps

- Fuel pumps

- Water pumps

- Irrigation pumps

- Turbine pumps

- Recirculation pumps

- Sewage pumps

Common brands we can repair include, but are not limited to:

- All-Flo

- Bush Vacuum

- Hamilton

- Goulds

- Graco

- Tonkaflo

- Duravac

- Viking

- And more

Regardless of your industry—whether plastics manufacturing, food processing, power generation, or fuel production—you can rely on the talented experts at All Geared Up to repair and replace your pumps to proper specifications.

We’ll ensure whatever caused the pump to fail is fixed, as well. If you have a leak in your line, we can find it and get that taken care of, too.

No pump is too large or too small for our professionals. We can service everything from giant industrial pumps down to the smallest specialty pumps and everything in between. The team at All Geared Up is available 24/7 to get your equipment back up and running.

We understand that an equipment failure can mean thousands of dollars in productivity lost. When you have an emergency, All Geared Up will be there!

We’ll perform a thorough diagnosis of the system and go over the necessary repairs with you. Trust the experts at All Geared Up to get your pumps running again!

Hydraulic Equipment Repair

Hydraulic equipment repair can be complex and messy, especially if you aren’t sure how to do it properly. At All Geared Up, we make things easy. Our skilled team can service any hydraulic equipment you rely on, including, but not limited to brands like:

- Bobcat

- Hitachi

- Komatsu

- Massey

- Caterpillar

- John Deere

- Eaton

- Mitsubishi

- Ford

- Torquemaster

- And many more

Hydraulic systems are particularly sensitive to leaks and wear. It’s essential for hydraulic systems to maintain a perfect closed loop. When leaks happen, it’s not just frustrating to lose precious fluid and stain your facility floor—it also means there are contaminants making their way into your hydraulic system!

This contamination can prematurely wear out parts and even destroy them. As the contaminants make their way through, they’ll make the system less efficient.

With enough debris in the system, not only will your parts wear out faster, but they’ll also work slowly and with poor tolerances.

You might wonder why the industry hasn’t moved to pneumatic systems by this point, since air is sometimes easier to deal with than hydraulic fluid.

Air is far more compressible than a liquid, so hydraulic fluid transfers energy much more efficiently than any pneumatic system is capable of doing. Pneumatics are excellent, and they make for a much cleaner working environment during repairs, but they’re not right for every job.

If you rely on hydraulic machinery to keep your facility running, turn to the team at All Geared Up to keep your machines running right.

Gear Manufacturing

Gears need to be precise. When there is buildup and debris in a gear set, it’s not only irritating to hear clunking sounds; it can also result in poor tolerances and premature wear.

Even when equipment does have brilliantly crafted gears, they will still wear down or break over time. In some cases, a facility will rely on a piece of machinery that’s no longer in production or a component that was produced by a manufacturer that is no longer in business.

At All Geared Up, we can help. When you realize that your machine needs a new gear and you don’t know where to get it, our skilled professionals can make a new one.

- Bevel gears

- Split herringbone gears

- Spiral bevel gears

- Helical gears

- Herringbone gears

- Worm gears

- Girth gears

- Pinions

When you call us in to inspect your broken or poorly working equipment, we do a full inspection to find any flaws. If the issue happens to be a broken gear and a new one can’t be sourced, we’ll go ahead and make one!

Shovel and Dragline Components

- OEM quality or better

- Guaranteed to drop in

- Modifications to gear ratios possible

Drives

- Mine hoist geared drives

- Dredge drive gears

- Slurry pump drives with custom ratios

- Barring drives and clutches

Gearboxes

Work we can perform on gearboxes include:

- Improving gear tooth profiles, thermal ratings, and bearing life

- Changing number of reductions and ratios

- Improving lubrication

Even if you can source a new gear for your essential equipment, you might find that we can make it for less than what the manufacturer is charging.

The best part is we can make gears of any size. From tiny precision gears that need to be installed with tweezers to hefty gears that are taller than a person, All Geared Up can grind it.

Our tolerances are accurate within ten-thousandths of an inch, and our gears are guaranteed to work as well or better than an OEM solution.

To learn more, give us a call today.

Preventative Maintenance

Broken equipment can lead to downtime on the production line, thousands of dollars in ruined product, and other significant consequences. When you want to keep your equipment running properly, preventative maintenance is the best way to do it.

So many problems you could face with your gearboxes, pumps, and hydraulic equipment can be avoided with routine preventive maintenance.

- Drives for winches, winders, slews, pumps, etc.

- Shovel and dragline

- Gears for jack up rigs, rotary tables, girth gears, etc.

- Levellers

- Stacker reclaimers

And once you’re on a schedule with us, you don’t have to worry about your equipment wearing out without you knowing about it!

At All Geared Up, our skilled technicians have the expertise to keep your machinery running up to and beyond its expected service life. We can perform all types of preventative maintenance, including:

- Lubricating parts on a set schedule

- Regularly inspecting for wear and tear

- Making adjustments

- Checking tolerances

- Changing fluids

You can also request that we perform other services as needed. We’ll work with you and get on a routine preventative maintenance schedule that fits in with your manufacturing process, allowing your facility to run with minimal interruption and downtime.

Our team can also show you some basic procedures and checks that you and your staff can perform to ensure long machine life.

If your machinery does need repair, we’re available 24/7 to help you get it fixed.

When your equipment has reached the end of its recommended service life, we’ll inspect it to see what components may need to be replaced. Many times, changing out some moving parts can keep a piece of machinery running many years past when it might otherwise have been discarded.

For all of your equipment maintenance needs, turn to the team at All Geared Up.